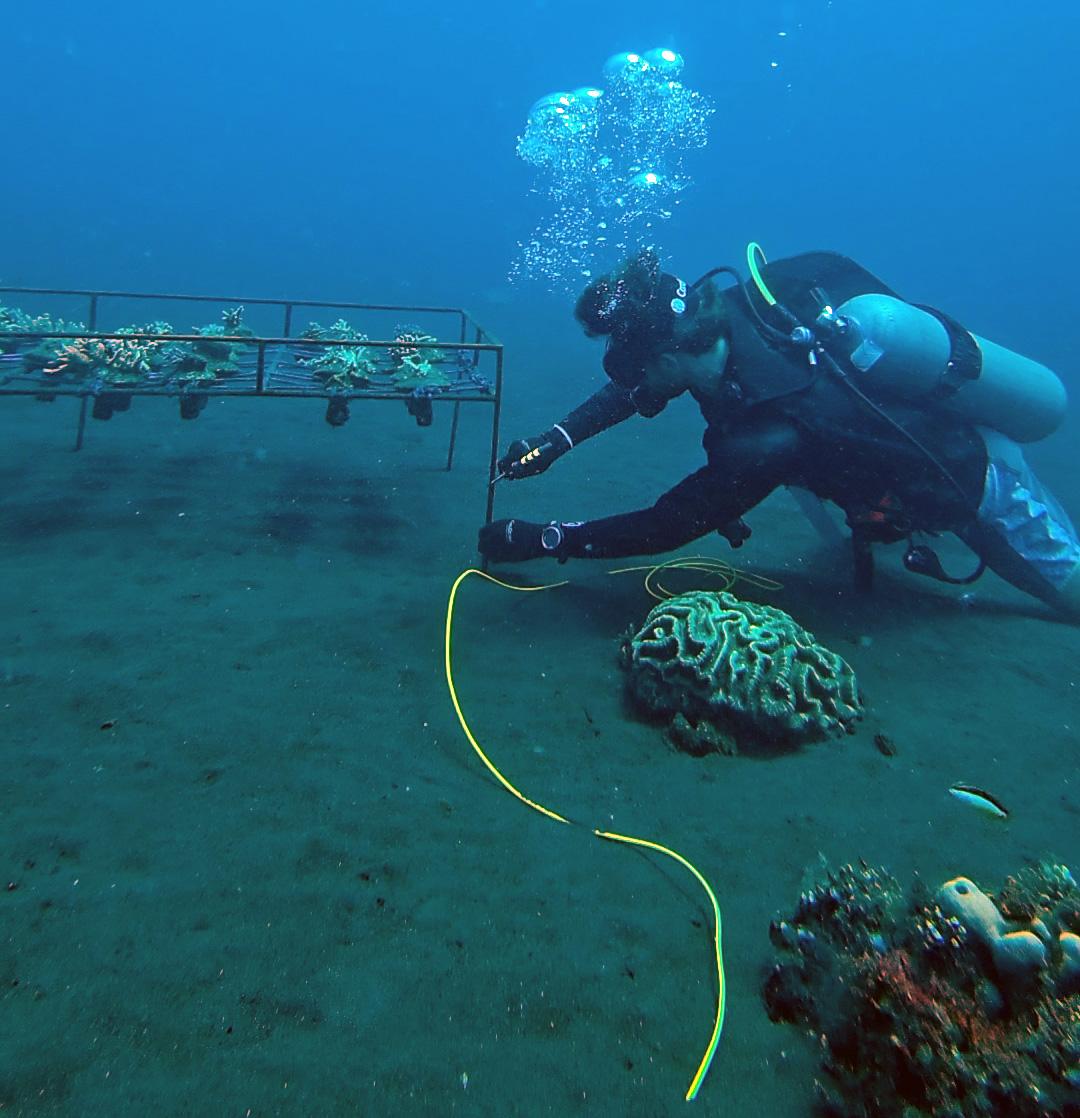

On 8 July 2025, Ocean Gardener established a pilot program to test the Mineral Accretion Technology (MAT) in front of our partners, the MERO Foundation, in Tulamben, East Bali. Our goal was to observe firsthand if MAT truly promotes faster and healthier coral growth. We will also be able to compare the result with other methods that are also used in the same area. We also wanted to challenge ourselves by sourcing the best possible quality components and keeping costs as low as possible, and to evaluate whether the increased costs in electricity and materials are outweighed by the benefits of accelerated and more robust growth. For this, we partnered with our good friend Coralive, from Switzerland, who helped us source all components, from the very complex carbon-titanium anode, the efficient power supply, and all the other high-quality electrical bits. They also sent their best technicians to install the whole structure with us.

In this age where corals are being threatened from every angle, we need every possible tool to help them grow faster and conserve their biodiversity in the hunt for thermoresilient corals to cope with ongoing global warming. Could electrified reefs be a coral restoration tool to we could use to grow corals faster?

What is Mineral Accretion Technology?

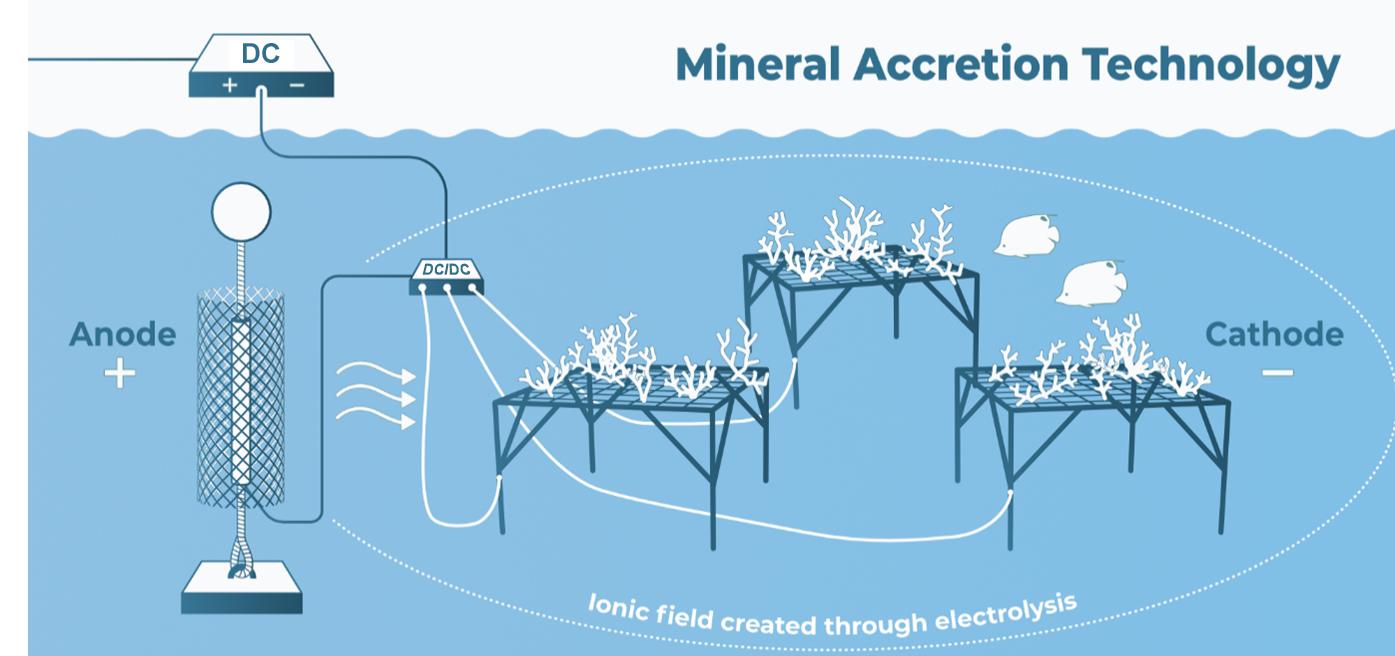

Mineral Accretion Technology is a method that uses a low-voltage electrical current passed through seawater to promote the growth of submerged mineral structures.

When a low electrical current is applied to metal structures submerged in seawater, it triggers an electrochemical reaction. This reaction causes minerals naturally dissolved in the water, primarily calcium carbonate (CaCO3) and magnesium hydroxide (Mg(OH)2), to precipitate and accrete onto the surface of the structures, forming a solid, limestone-like material.

Corals growing on these structures often exhibit accelerated growth rates and increased resilience to environmental stressors like ocean acidification and warming. This is attributed to several factors:

- Enhanced Calcification: The electrical current creates an alkaline (higher pH) microenvironment directly at the surface of the growing structure. Corals naturally expend significant energy to create these alkaline conditions within their own tissues to facilitate the calcification process (building their calcium carbonate skeletons). By providing these optimal conditions externally, the technology reduces the energetic cost for the corals, allowing them to allocate more energy towards growth, reproduction, and repair.

- Increased Mineral Availability: The constant precipitation of calcium carbonate directly on the structure means there’s a localized, readily available supply of the building blocks for coral skeletons, further accelerating their growth.

- Reduced Stress: The stable environment and constant supply of essential minerals can make corals less susceptible to stressors that would otherwise cause bleaching or mortality, such as elevated water temperatures or pollution. The generated limestone also provides a stable substrate for coral attachment and growth.

While the exact mechanisms are still being researched, the fundamental principle is that the electrical field effectively “primes” the environment for coral growth. Corals do not need to spend so much energy to build their skeletal structures. The energy saved can be spent on accelerating growth, fighting infections and natuarl reproduction via spawning.

Locally sourced materials where possible

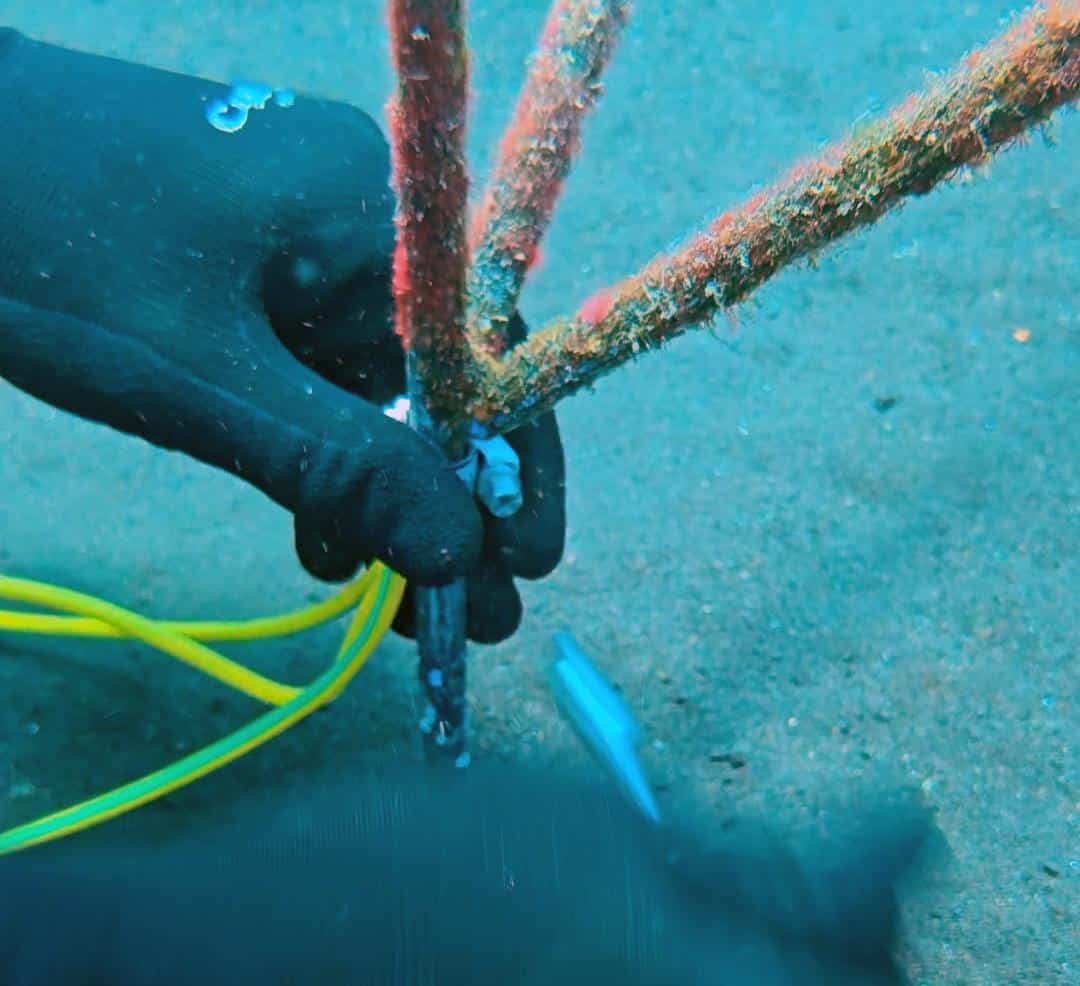

We explored many local and foreign options with our eyes on the costs and finally identified our approach. Unfortunately, good quality, ready-made components for the actual Mineral Accretion Technology anode and power supply were hard to source locally here in Indonesia. We partnered with our good friend Coralive, from Switzerland, who helped us source the special carbon-titanium anode and the efficient power supply. The main cable, connecting cables, clamps, iron structure (table and reef stars), connection sealing resin and electrical panels were all sourced locally to keep costs down.

The anode is made of carbon, with a Titanium mesh around it. Very specific cables were necessary to carry this lower voltage current and distribute it evenly. The reef stars and tables are made out of normal steel rebars.

Mineral accretion prevents the steel from rusting as the low-voltage electrical current passes through the reefstars, causing dissolved minerals in the seawater to crystallize onto the metal. This forms a hard, limestone-like coating that acts as a protective barrier, preventing rust while also providing a perfect surface for corals to grow on.

The cost to impact ratio is especially important to us as we want our donation funds to plant as many corals as possible.

Arrange of coral restoration structures and anode

The idea is to have a homogeneous ring of tables, and another ring of reef stars, around the Anode. Every structure of the same size is at the same distance from the Anode as the other ones, yet receiving exactly the same electrical field as the others.

Next steps?

Hopefully, this process entirely eliminates the need for petroleum resin and plastic cable ties as the Reefstars become naturally coated by a layer of calcium carbonate from the electricity passing through the structure, which provides an ideal substrate for coral settlement.

Corals are first cultivated on nursery tables, with fragments subsequently transferred to the MAT-connected reefstars. Once the reefstars are thoroughly colonized, they will be detached from the electric current and relocated to the designated restoration area, making way for new reefstars.